Körber Supply Chain Software and Tchibo strengthen their long-standing partnership

The opening of the Cheb distribution center marks a milestone along Körber Supply Chain Software and Tchibo’s joint journey of “supply chain excellence”

Hamburg, 18 September 2024.

The opening of the Cheb distribution center marks a milestone along Körber Supply Chain Software and Tchibo’s joint journey of “supply chain excellence”

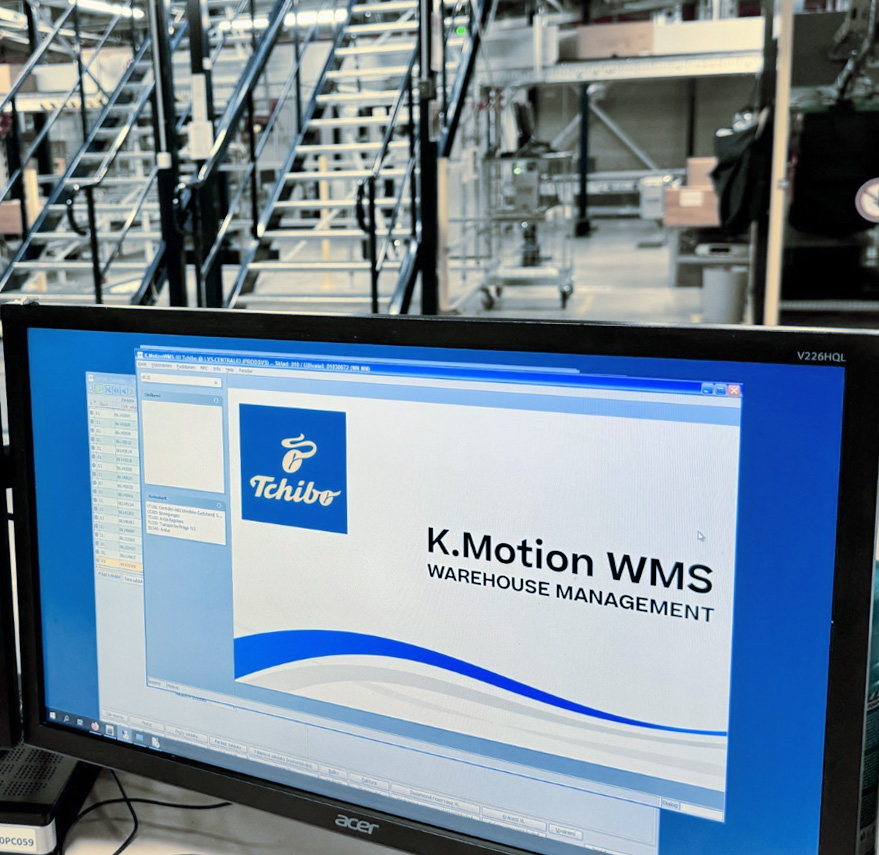

Tchibo, a market leader in the roasted coffee and non-food segment, has partnered again with Körber to transform its logistics landscape. While Tchibo has relied on Körber's Warehouse Management Systems (WMS) within its logistics network for many years, the WMS system was recently implemented as part of the Czech distribution center in Cheb. The goal for Tchibo is to achieve a more sustainable flow of goods for its B2C business.

With the official go-live of the significantly expanded and largely automated logistics site in Cheb, Körber and Tchibo have committed to their 25-year partnership. In 1999, the first Tchibo warehouse began operating with a warehouse system from Körber. Körber's WMS, Warehouse Control System (WCS) and Yard Management System (YMS) have now been implemented at numerous Tchibo locations. Today, Körber's WMS controls all the multi-channel retailer's warehouses - and enables high reliability, flexibility and efficiency as it supplies approximately 900 Tchibo stores and more than 10,000 stationary points of sale (POS).

Tchibo now concentrates fulfillment for the online B2C business and European returns exclusively at its Cheb location. At peak times, the number of orders processed in Cheb rises to high, five-digit numbers. There, Tchibo has centralized the handling of returned goods to feed back into the order cycle. This transformative process included the integration of modern automation and conveyor technology components. A pocket sortation system with 100 pack stations manages returned, out-of-stock products directly to make them available for sale again. In total, the WMS controls and monitors 320 workstations. The pocket sortation system exchanges up to two million messages a day with the WMS. The process, which is anchored in the WMS, optimizes the goods cycle with minimal expenditure of time and resources.

“Optimizing inventory systems is not just a question of the right technology. It's also about scrutinizing current processes,” says Michael Brandl, EVP EMEA at Körber Supply Chain Software. “Körber's shipping and returns study, for example, found that 30.5% of German consumers still make 2-3 returns per month. In view of the impact on people and the environment, logistics concepts for efficient and sustainable returns logistics are becoming increasingly important.”

“For us, there is no alternative to a more sustainable use of our goods and resources. In Cheb, we have taken another important step towards more sustainable logistics with the new technology and control system. At the same time, we are already looking at other potential areas for optimization.”

The expansion of the site, integration of the automation and conveyor technology and the implementation and connection of Körber’s WMS are ongoing projects since mid-2021. Körber put new plant areas into operation step by step.