Prioritize modular, architecture

Build connected execution without rip-and-replace cycles.

Organizations agree: competitive advantage now comes from fast, connected, intelligent execution, not isolated systems or static planning

Modern supply chains face increasing volatility: disruptions, delays, rising costs and missed commitments are now the norm rather than the exception. The research reveals a clear gap between what leaders know must change and what current execution environments can support.

Key findings

INSIGHT 1

79% of leaders say competitive advantage comes from fast, dynamic execution vs. traditional planning.

Top investment drivers:

Execution is where performance breaks and where value is unlocked.

INSIGHT 2

Top sources of inefficiency:

Execution is where performance breaks and where value is unlocked.

“Only 20% of companies have real time visibility across execution. Most organizations still react to issues instead of anticipating them.”

INSIGHT 3

Modernization is not failing due to lack of budget but due to outdated systems.

Top barriers:

INSIGHT 4

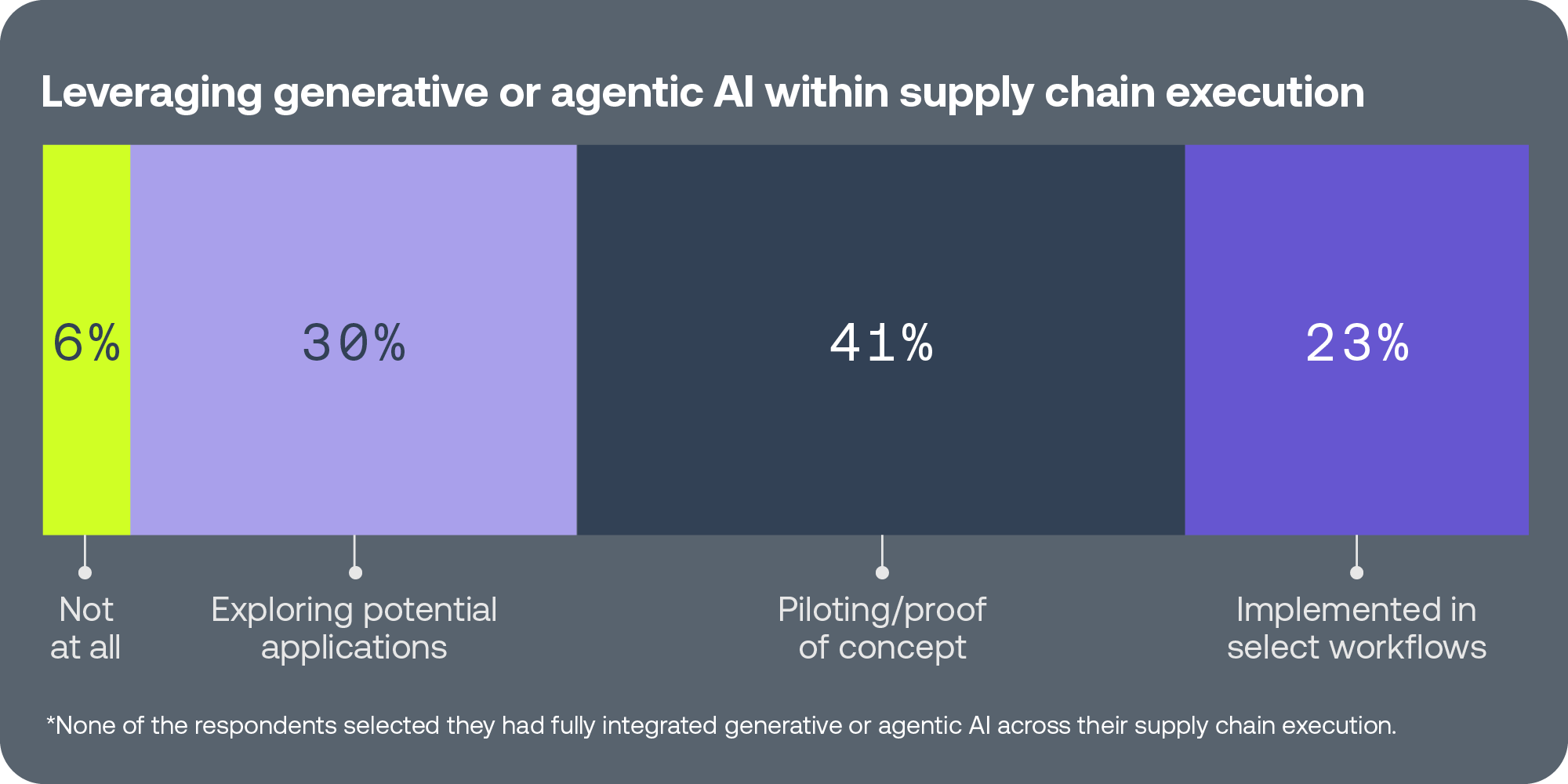

Interest in artificial intelligence is high across supply chain organizations, but survey results show a clear gap between ambition and real-world impact.

AI adoption status:

Top barriers to scaling AI:

Build connected execution without rip-and-replace cycles.

Even with imperfect data, operational AI learns and improves over time.

AI must drive decisions and action across OMS, WMS and TMS.

Get the complete 16 page research report,

including industry breakdowns and recommendations.